As of September 2021, the smallest PCB (Printed Circuit Board) is the one inside the Michigan Micro Mote (M^3) which was developed by the University of Michigan. The entire device, including the PCB, measures just 1 cubic millimeter. The exact dimensions of the PCB itself are not often disclosed but they must fit into this incredibly tiny form factor. The M^3 is a complete computer system and includes RAM, flash memory, a processor, and even a solar cell for power.

As technology advances, smaller PCBs are continuously being developed. Please verify this information with the most recent sources.

There are no technical limitations to the size of a PCB, and it is theoretically possible to create a PCB with a size of a few micrometers. The smallest PCBs are typically used in medical devices, wearable electronics, and other applications where space is limited.

Factors that affect the size of a PCB:

- The number of components:

The more components that are on a PCB, the larger it will need to be. - The size of the components:

The size of the components will also affect the size of the PCB. - The type of PCB:

There are different types of PCBs, such as single-sided, double-sided, and multilayer PCBs. The type of PCB will also affect the size. - The manufacturing process:

The manufacturing process used to create the PCB will also affect the size.

The cost of a PCB increases as the size decreases because it is more difficult and expensive to manufacture small PCBs.

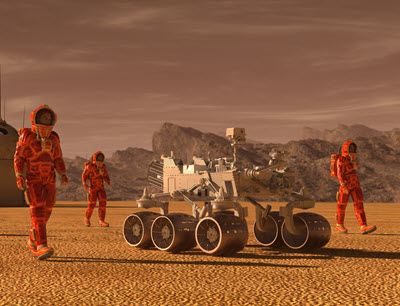

Harsh Environments

Printed Circuit Boards (PCBs) are not easily degraded in the environment. They are typically made of materials that are quite resilient to environmental factors, such as fiberglass or metal, and they're designed to be durable and long-lasting.

Printed Circuit Boards (PCBs) are not easily degraded in the environment. They are typically made of materials that are quite resilient to environmental factors, such as fiberglass or metal, and they're designed to be durable and long-lasting.

Any sized PCBs, including micro-PCBs, can be designed to handle harsh environments, but it often requires special design considerations and additional protective measures.

Harsh environments could include:

- High or low temperatures

- Moisture

- Vibration

- Shock

- Dust

- Corrosive chemicals

To protect PCBs from these kinds of conditions, a variety of techniques can be used:

Conformal Coating:

This is a protective chemical coating or polymer film that 'conforms' to the circuit board topology. Its purpose is to protect electronic circuits from harsh environments that may contain moisture, chemical contaminants, or extreme temperatures.

Potting:

This is the process of filling a complete electronic assembly with a solid or gelatinous compound for resistance to shock and vibration, and for exclusion of moisture and corrosive agents.

Rugged Components:

Using components that are specifically designed to withstand harsh conditions.

Design Techniques:

Implementing various design techniques such as strategic component placement, use of heat sinks, thermal relief pads, and others can also help.

Overengineering:

Designing the PCB to exceed normal specifications can provide a buffer against harsh conditions.

Use of robust materials:

Certain materials are more resistant to harsh conditions, such as certain plastics or metals for the board material.

There are practical limits to these protection methods and, in extremely harsh conditions, even these might not be sufficient. Additionally, the smaller the PCB (especially in the case of micro-PCBs), the harder it might be to implement some of these protection methods. For instance, applying a rugged casing or conformal coating might be more challenging on a micro scale.

Steps involved in designing PCBs for harsh environments:

- Material Selection:

Choose the right materials that can withstand the harsh environment. For high-temperature environments, use high-temperature laminates. In environments with high moisture or corrosion, use materials that are resistant to these conditions. - Component Selection:

Use components that are rated for operating conditions. Military-grade or industrial-grade components often have wider operating temperature ranges and higher resistance to various environmental conditions. - PCB Layout Design:

Design the PCB layout with harsh environments in mind. This could mean placing heat-sensitive components away from heat sources, minimizing trace lengths to reduce potential for signal degradation, and avoiding sharp corners to reduce electromagnetic emissions and susceptibility. - Conformal Coating:

Conformal coatings are often used to protect PCBs from moisture, dust, chemicals, and temperature extremes. This is a protective chemical coating or polymer film that 'conforms' to the circuit board topology. - Potting and Encapsulation:

Potting involves encasing the entire PCB in a solid or gelatinous compound. This protects against shock, vibration, moisture, and corrosive agents. - Thermal Management:

High temperatures can damage electronic components and reduce the lifespan of the PCB. Consider heat sinks, thermal pads, vias, and other cooling methods to manage heat. - Mechanical Stress Management:

If the PCB will be subjected to high vibration or mechanical stress, design the board to minimize these stresses. This could involve using thicker boards, adding mounting holes, or using stiffer materials. - Testing:

Finally, it's critical to test the PCB under conditions that simulate the harsh environment in which it will be operating. This could involve high-temperature testing, vibration testing, or testing the PCB under the actual conditions it will be used.

Designing PCBs for harsh environments usually requires trade-offs and might increase the cost of the PCB. It's important to understand the specific requirements of the environment and to design the PCB to meet those needs. Always check for the most recent standards and technological updates in PCB design for harsh environments.

There is continuous research and development to enhance the durability of microelectronics, including micro-PCBs, in harsh conditions. It's always a good idea to check with our manufacturers for the most recent technological updates.

If you are looking for a PCB (or micro-PCB), you will appreciate working with our premiere manufacturers. They will be able to help you design and manufacture a PCB that meets your needs and budget.

Please send us your requirements and let our experienced team provide solutions for you.

A 'complete capability' service is available, including in-house engineering, component manufacturing, assembly & technical sales support.

Don't hesitate to contact us if you need support!

Our Premiere Manufacturers that offer PCBs: