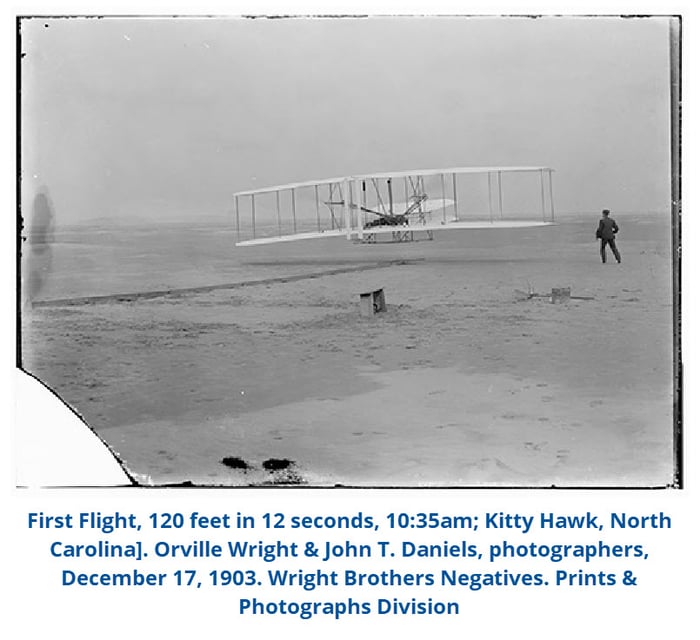

Regarding disruptive technology, a 120th Anniversary will be celebrated soon.

On the morning of December 17, 1903, Wilbur and Orville Wright took turns piloting and monitoring their flying machine in Kill Devil Hills, North Carolina. Orville piloted the first flight that lasted just 12 seconds and 120 feet. On the fourth and final flight of the day, Wilbur traveled 852 feet, remaining airborne for 59 seconds. That morning, the brothers became the first people to demonstrate sustained flight of a heavier-than-air machine under the complete control of the pilot. Read more at Library of Congress.

They were thought to be insane, crazy, con artists and scammers. even after the first flight.

“For an idea that first does not seem insane, there is no hope.”

- Albert Einstein

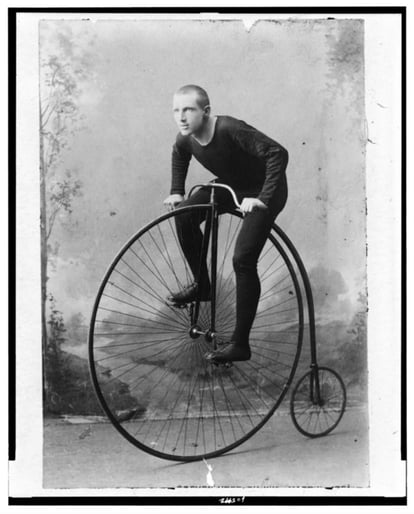

Prior to that, the bicycle was a big disruption. The advent of the bicycle in the late 19th century transformed societies the world over. It was a hugely disruptive technology, easily the equivalent of the smartphone today. For a few heady years in the 1890s, the bicycle was the ultimate must-have—swift, affordable, stylish transportation that could whisk you anywhere you cared to go, anytime you liked, for free. There was also a moral and medical panic over bicycles!

Prior to that, the bicycle was a big disruption. The advent of the bicycle in the late 19th century transformed societies the world over. It was a hugely disruptive technology, easily the equivalent of the smartphone today. For a few heady years in the 1890s, the bicycle was the ultimate must-have—swift, affordable, stylish transportation that could whisk you anywhere you cared to go, anytime you liked, for free. There was also a moral and medical panic over bicycles!

--

Much of the transformation in manufacturing is driven by the adoption of disruptive technologies such as artificial intelligence (AI), machine learning (ML), the Internet of Things (IoT), and 3D printing. These technologies disrupt traditional manufacturing processes and enable new ways to design, produce, and deliver products.

For example, AI and ML are used to automate tasks, improve quality control, and optimize production schedules. The IoT connects machines and devices, collects data, and monitors real-time operations. And 3D printing is used to create customized parts and products on demand.

These disruptive technologies are having a significant impact on the manufacturing industry. They are helping manufacturers to improve efficiency, reduce costs, and create new products and services. As a result, the manufacturing industry is becoming more agile, flexible, and responsive to market demands.

In this article, we will introduce you to disruptive technological innovations. We will discuss the key technologies that are driving this transformation.

- Artificial Intelligence - AI and machine learning are disrupting many industries by automating tasks and processes previously done by humans. Examples include chatbots for customer service, recommendation engines for e-commerce, and autonomous vehicles.

- Autonomous vehicles - Autonomous vehicles that can drive themselves without human intervention are still in development, but they have the potential to revolutionize transportation.

- Quantum computing - Quantum computing is a new type of computing that uses the principles of quantum mechanics to perform calculations. It is still in its early stages of development, but it has the potential to revolutionize many industries, such as drug discovery and materials science.

- 5G - The rollout of high-speed 5G wireless networks enables new technologies like smart cities, VR/AR, connected healthcare, and autonomous vehicles that need colossal bandwidth and low latency.

- Space Commercialization - Companies like SpaceX and Blue Origin are paving the way for commercial space travel and satellite deployments.

- Edge computing - Edge computing is a distributed computing paradigm that brings computation and data storage closer to the end user. This can improve performance and reduce latency, especially for applications that require real-time processing.

- Blockchain - The decentralized ledger technology behind cryptocurrencies like Bitcoin disrupts finance, supply chain, and other industries by removing intermediaries.

- Web3 - Web3 is a new iteration of the internet that is built on blockchain technology. It promises to be more decentralized and secure than the current web. You will see Web3 used in:

- Supply Chain - Using blockchain to record and track product data provenance transparently through supply chain networks.

- Identity Management - Self-sovereign identity that allows people to own and control their digital identities without central authorities.

- Funding - Crowdfunding - Replacing centralized crowdfunding sites with decentralized funding powered by cryptocurrencies and smart contracts.

Internet of Things (IoT) - Connecting everyday objects to the internet enables industrial IoT to disrupt traditional businesses. IoT generates invaluable manufacturing data, enhances automation, improves supply chain integration, and empowers enterprise-wide operational efficiency gains. It is a crucial enabler of the smart, connected factories of the future.

Internet of Things (IoT) - Connecting everyday objects to the internet enables industrial IoT to disrupt traditional businesses. IoT generates invaluable manufacturing data, enhances automation, improves supply chain integration, and empowers enterprise-wide operational efficiency gains. It is a crucial enabler of the smart, connected factories of the future.

- Machine monitoring - Sensors on equipment provide real-time data on machine performance, utilization, vibrations, temperature, etc. IoT enables predictive maintenance while monitoring equipment.

- Inventory management - IoT devices like RFID tags track materials, parts, and finished products throughout facilities and the supply chain to provide real-time visibility.

RFID TECHNOLOGY! We recently attended and were fascinated at a CAMPS event where Andy Zosel, the Sr. VP/GM of Advanced Data Capture, Machine Vision & Imaging, took a deep dive and helped us unravel the intricate tapestry of technology disruptions reshaping the manufacturing landscape.

We were impressed by the new RFID technology by Zebra Technology that tracks every movement and result of every player on the football field.

-

- Quality control - Sensors perform real-time quality checks during production, detecting defects and triggering alerts to improve quality.

- Automation and control - IoT devices like PLCs automate and remotely control manufacturing processes like assembly lines and robotics arms.

- Supply chain integration - IoT enables data sharing and visibility across suppliers, manufacturing facilities, warehouses, etc., for coordination.

- Fleet management - GPS tracking and telematics in company vehicles and transport trucks for efficient routing, utilization, and shipment tracking.

- Worker safety - Wearables track worker health data and environmental conditions to improve workplace safety and prevent accidents.

- Energy management - Smart meters and sensors connected to utility infrastructure improve energy efficiency of operations.

- Building management - IoT devices monitor and control lighting, HVAC, security, etc., to improve facility operations.

- Neural Interfaces and Brain-Computer Interfaces (BCI) - Neural and brain-computer interfaces (BCI) are still in early research and development stages and have limited applications in manufacturing so far. The future sounds a little like science fiction, but some potential uses could be:

- Advanced Human-Machine Interfaces: BCIs could enable operators to control machines or robotics intuitively using thought beyond keyboards, gestures, or voice commands. This can improve precision and productivity.

- AR/VR Operations: Neural interfaces paired with AR/VR headsets may allow workers to control digital twins of machines or access manufacturing data hands-free through thought.

- Training: BCIs could be used for accelerated training by allowing workers to upload knowledge or manual skills to the brain quickly.

-

Safety: Neural interfaces could directly sense fatigue and distress signals from the worker's brain to improve workplace safety and prevent accidents.

Safety: Neural interfaces could directly sense fatigue and distress signals from the worker's brain to improve workplace safety and prevent accidents. - Quality Inspection: Brain signals may assist in defect detection during quality inspection to improve accuracy beyond visual means.

- Exoskeleton Control: Paralyzed workers may be able to control powered exoskeletons using just brain signals, granting mobility.

- Analytics: Collecting mental workload and worker satisfaction data could optimize manufacturing processes.

- Renewable Energy Technologies - Wind, solar, and other renewable energy sources are becoming more efficient and cost-effective, challenging the dominance of fossil fuels.

- Cloud Computing - The ability to access computing power, storage, and applications over the internet is changing how businesses maintain infrastructure and develop software.

- Augmented/Virtual Reality - AR and VR are disrupting gaming, retail, healthcare, education, and training by enhancing human interaction with the digital world.

- 3D Printing - Also known as additive manufacturing, 3D printing disrupts manufacturing and product design by enabling cheap, customized, on-demand production. 3D printing grants unprecedented control over product geometry, customization, decentralization of production, and reductions in lead times across many industries. It enables next-generation manufacturing capabilities. Ways 3D printing is already integrated into manufacturing:

- Prototyping - Printing prototypes of products, parts, and industrial equipment quickly and cost-effectively for design verification and testing.

- Customized Production - Producing small batches of highly customized end-use products tailored to customer specs without expensive retooling.

- Spare Parts - On-demand printing of spare parts for maintenance and repairs rather than expensive warehousing.

- Tooling - 3D printing molds, casts, fixtures, and jigs that enable shorter tooling lead times.

- Lightweighting – 3D printing increases the ability to optimize designs for weight reduction using 3D printing's geometric freedom. Industries like aerospace benefit from this in a big way.

- Supply Chain - 3D printing brings production closer to the point of use by enabling distributed manufacturing models and reducing shipping.

- Aftermarket - Companies leverage 3D printing to produce aftermarket parts to extend product lifespan.

- Bio-fabrication - 3D printing of human tissue and organs using bio-inks is entering manufacturing for healthcare.

- Food - 3D printing enables customized production of food items through precise control of ingredients. This is opening a new segment in manufacturing!

- Robots/Automation - Advanced robotics and automation are disrupting jobs and entire industries by replacing human labor for repetitive, dangerous tasks while reducing costs and human labor requirements across many industries:

- Assembly

- Welding

- Painting & Coating

- Material Handling

- Injection Molding

- Palletizing

- Quality Inspection

- Machining

- Hazardous Tasks

These examples of the many technological disruptions today remind us that being alive is an exciting time. It will be interesting to see how these technologies shape our world in the years to come.

While not definitive, AI, IoT, autonomous vehicles, 5G, and blockchain have vast disruptive potential across industries and society. Though their effects are not visible, the scale of their impact will become more evident over time.

The MaRCTech2 team is considering the possibilities and how you need more advanced solutions. We work with a fantastic group of manufacturers we consider "premiere," and are committed to providing the best components and services.

Reach out to us with your questions and conundrums regarding your next project!

Contact us here!

P.S.

Here is a story about disruptive technology and a woodcutter.

We will call him "woodcutterman."

Woodcutterman was in Starbucks (or maybe it was Dunkin' Donuts), and he saw someone at the next table counting a stack of large bills. Curiosity got the best of him. He asked, "Hey! How did you make all of that money?" After a moment, the response came, "I cut wood and sold it. Every day, I go to the woods with my Stihl chainsaw, cut up a truck full of wood, and make hundreds of dollars daily."

Woodcutterman was in Starbucks (or maybe it was Dunkin' Donuts), and he saw someone at the next table counting a stack of large bills. Curiosity got the best of him. He asked, "Hey! How did you make all of that money?" After a moment, the response came, "I cut wood and sold it. Every day, I go to the woods with my Stihl chainsaw, cut up a truck full of wood, and make hundreds of dollars daily."

Woodcutterman was pretty excited. Believing he had discovered the way out of poverty, he immediately went to the store to buy a Stihl chainsaw, knowing he, too, would be counting stacks of large bills. The following day, he left for the woods and worked on filling his truck. He came back and made $30.

The next morning, he was up earlier, worked longer --- and made only $40.

The next morning, he was up before dawn, worked past dark, and skipped lunch. The result was $60.

He stormed into the store where he bought the saw and banged it on the counter.

"There is something wrong with this saw! I have only made a fraction of the money my friend makes."

The customer service rep looked at the saw and offered to test it. After looking it over, he takes hold of the handle, grabs a cord, and pulls.

The chainsaw starts right up with a roar.

Woodcutterman looks at the saw and yells: "What's that noise? What's that noise?"

------------------------------

While the story is not true, the moral of the story is a reality. Advanced technology never ceases to be amazing and sometimes confounds us as well. When the processes break and you hit a roadblock, reach out to us... we want to help.